Plastics

Precision Matters in Plastics Manufacturing

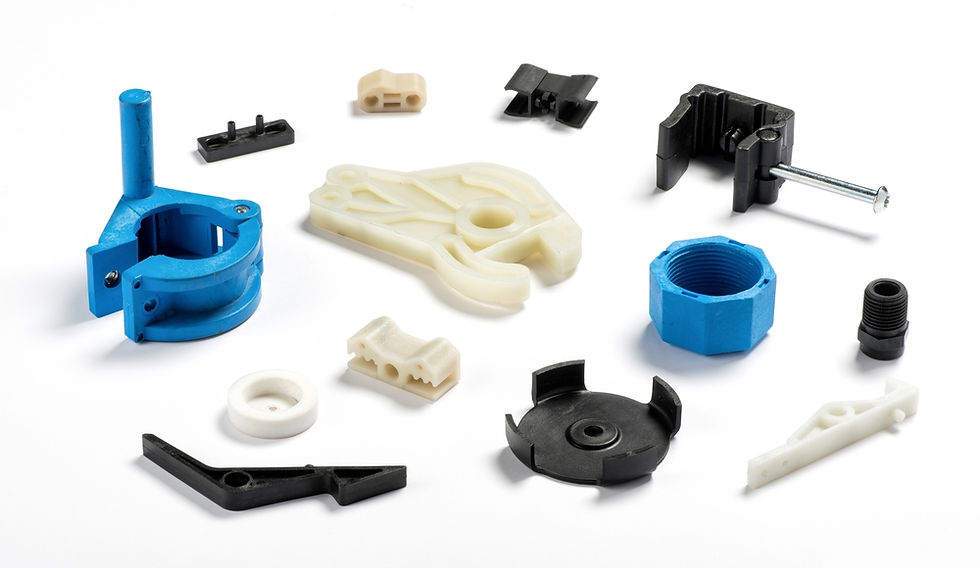

In the highly competitive plastics industry, where dimensional accuracy, appearance, and structural integrity are critical, metrology is fundamental to quality assurance and process optimization.

From injection-moulded components to thermoformed products, plastics manufacturers rely on advanced metrology systems to ensure product conformity, minimize defects, and maintain regulatory compliance.

The Role of Metrology in Plastics Manufacturing

Dimensional Verification and Tolerance Compliance - Metrology ensures that moulded or extruded plastic components meet exact tolerances for dimensions, wall thickness, and geometries—essential for fit, function, and safety.

Surface Defect Detection - Non-contact 2D and 3D inspection systems accurately detect surface anomalies, such as scratches, preventing defective parts from reaching customers.

Process Control and Optimisation - Real-time measurement data enables proactive adjustments to injection moulding, extrusion, or thermoforming processes—minimizing waste, reducing rework, and increasing efficiency.

Regulatory and Quality Standard Compliance - Industries such as automotive, aerospace, and medical devices require plastic components to meet strict international quality standards. Metrology ensures compliance and traceability throughout production.

Benefits of Using InspecVision Measurement Systems in the Plastics Industry

High-speed, non-contact inspection for complex plastic parts

Comprehensive 2D and 3D measurements in seconds

Early detection of defects, reducing scrap and rework

Easy integration into existing production and QA workflows

User-friendly reporting and data analysis tools for traceability

Industries

Discover our range of innovative industrial metrology machines

The aerospace industry uses an extensive range of components and assemblies that demand meticulous precision in manufacturing. Safety, regulatory requirements and faster production cycles all have a role to play in aerospace metrology.

Achieving this level of quality control can be problematic for aircraft manufacturers. OEMs and sub-contractors in the aerospace industry must implement comprehensive production traceability measures. Quality control reports at different stages of the manufacturing process are demanded.

The automotive industry is built on precision, safety, and efficiency. As vehicles become increasingly complex and customers demand higher quality, manufacturers must ensure every component meets strict tolerances and specifications.

Automotive metrology encompasses a wide range of requirements due to parts being produced in various locations. From product development to mass production, an extensive array of components and assemblies require high accuracy to function safely and efficiently.

In the medical device and healthcare sectors, precision is not optional, it’s a matter of safety, compliance and performance.

From implants and surgical instruments to diagnostic equipment and disposable devices, accurate measurement and quality control are critical at every stage of the medical manufacturing process.

In today's fast-paced packaging industry, where product integrity, sustainability, and brand reputation are on the line, ensuring precise measurements and defect-free packaging is more important than ever. Metrology, the science of measurement, plays a pivotal role in packaging quality control, helping manufacturers maintain consistency, meet compliance standards, and optimize production efficiency.

At InspecVision, we provide cutting-edge metrology systems that empower packaging companies to achieve unrivalled inspection accuracy, reduce waste, and drive profitability.

In the highly competitive plastics industry, where dimensional accuracy, appearance, and structural integrity are critical, metrology is fundamental to quality assurance and process optimization.

From injection-moulded components to thermoformed products, plastics manufacturers rely on advanced metrology systems to ensure product conformity, minimize defects, and maintain regulatory compliance.

Sheet metal fabrication is the process of forming metal sheets to the desired shape. It usually comprises multiple steps - through cutting and bending to surface treatment and assembling, serving various industries from prototypes to mass production.

In today’s competitive landscape, accuracy, efficiency, and quality are crucial. Precision inspection ensures parts meet design specs and industry standards.

InspecVision specializes in sheet metal inspection, addressing the industry's unique needs.

Customer Case Study

German owned Frantzen Discomatic specialise in discs which are used for wear parts in the grinding process. Having invested in a TRUMPF TruLaser laser cutting machine to improve the quality of parts and efficiency of production, quality control and inspection was still proving to be time-consuming and open to human error.